● Power supply: DC12~36V (APD300-L) or Battery (APD300-W)

● Measuring range: -70dBm~+10dBm;

● Measurement content: discharge amplitude, discharge frequency, discharge capacity, PRPD/PRPS map, etc.

● Communication: 1 RS485, MODBUS-RTU protocol (APD300-L); 1 channel Lora wireless communication (APD300-W);

● Strong anti-interference ability, high reliability.

● Magnetic installation

● Application scenario: Suitable for integrated installation of medium voltage switchgear (61 cabinets, 28 cabinets, ring main unit) before leaving the factory or for power-off installation of high-voltage switchgear that has already been put into use.

General

At present, the power system has increasingly high requirements for the quality of electricity, not only to ensure stable and reliable power supply, but also to ensure the safety of power supply. In the power system, metal enclosed switchgear is widely used, so the stability and reliability of the switchgear operation is of utmost importance. Electrical equipment, due to high temperature, voltage, vibration, and other chemical effects during operation, will have a reduced insulation performance, resulting in partial discharge and accelerating the deterioration of insulation, causing significant economic losses to the power system. However, due to the narrow internal space, numerous components, complex structure, and small insulation distance of the switchgear, it is more prone to insulation defects than other power equipment, which poses a huge hidden danger to the safe operation of the equipment.

Defects such as bubble gaps, impurities, and spikes in the insulation of high-voltage electrical equipment can cause uneven distribution of electric field inside the switchgear insulation under the action of strong electric fields. The electric field strength at the defect area will increase, which can easily lead to partial discharge that does not penetrate the entire insulation, that is, partial discharge.

Partial discharge generally does not cause penetrating breakdown of the insulation inside the switchgear, but it can lead to local damage to the insulation medium. If it exists for a long time, it will cause damage to the electrical strength of the insulation device under certain conditions, ultimately leading to insulation breakdown inside the switchgear. Therefore, for electrical equipment, the occurrence of partial discharge is one of the important reasons for insulation aging, deterioration, and even damage, leading to equipment damage and power system accidents. At the same time, partial discharge is also a sign of equipment insulation integrity degradation. Therefore, monitoring and detecting partial discharge of electrical equipment is an important means to evaluate the insulation status of equipment, and is also one of the effective measures to detect potential faults in equipment, ultimately achieve fault warning, and avoid the occurrence of faults.

APD series high-voltage switchgear partial discharge monitoring device detects the electromagnetic wave radiation generated along with partial discharge and automatically determines the actual detection frequency of on-site partial discharge. Then, data such as the number and frequency of partial discharge detected are uploaded to the server.

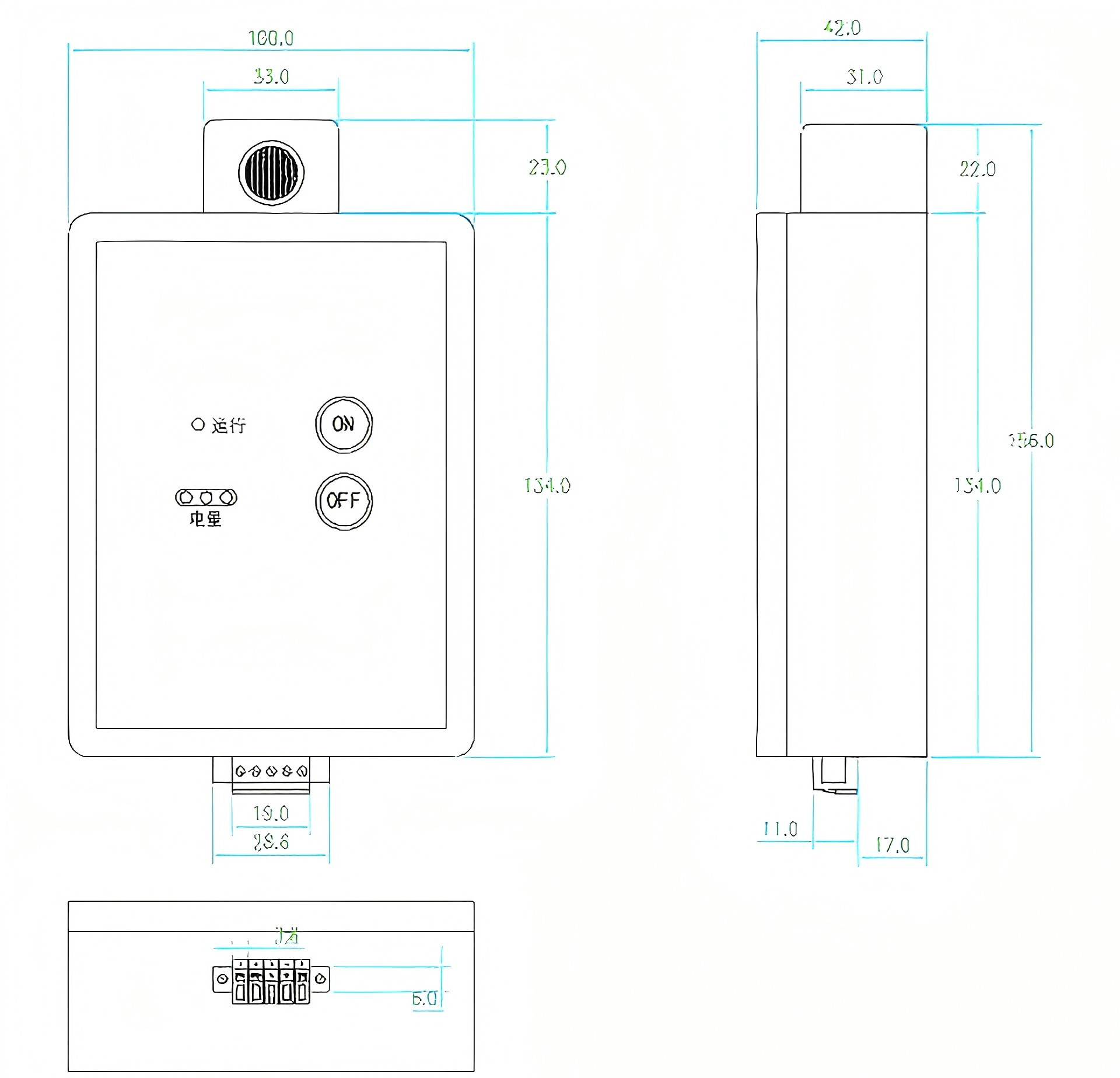

Dimension & Installation

APD300-L triple-in-one wired partal discharge sensor adopts a strong magnetic adsorpton mounting method and is installed on the cabinetwall in the cable compartment of the switchgear, The detailed dimensions of the product are shown in the figure, in mm.

APD300-L Dimensional

APD300-L triple-in-one wired partial discharge sensor

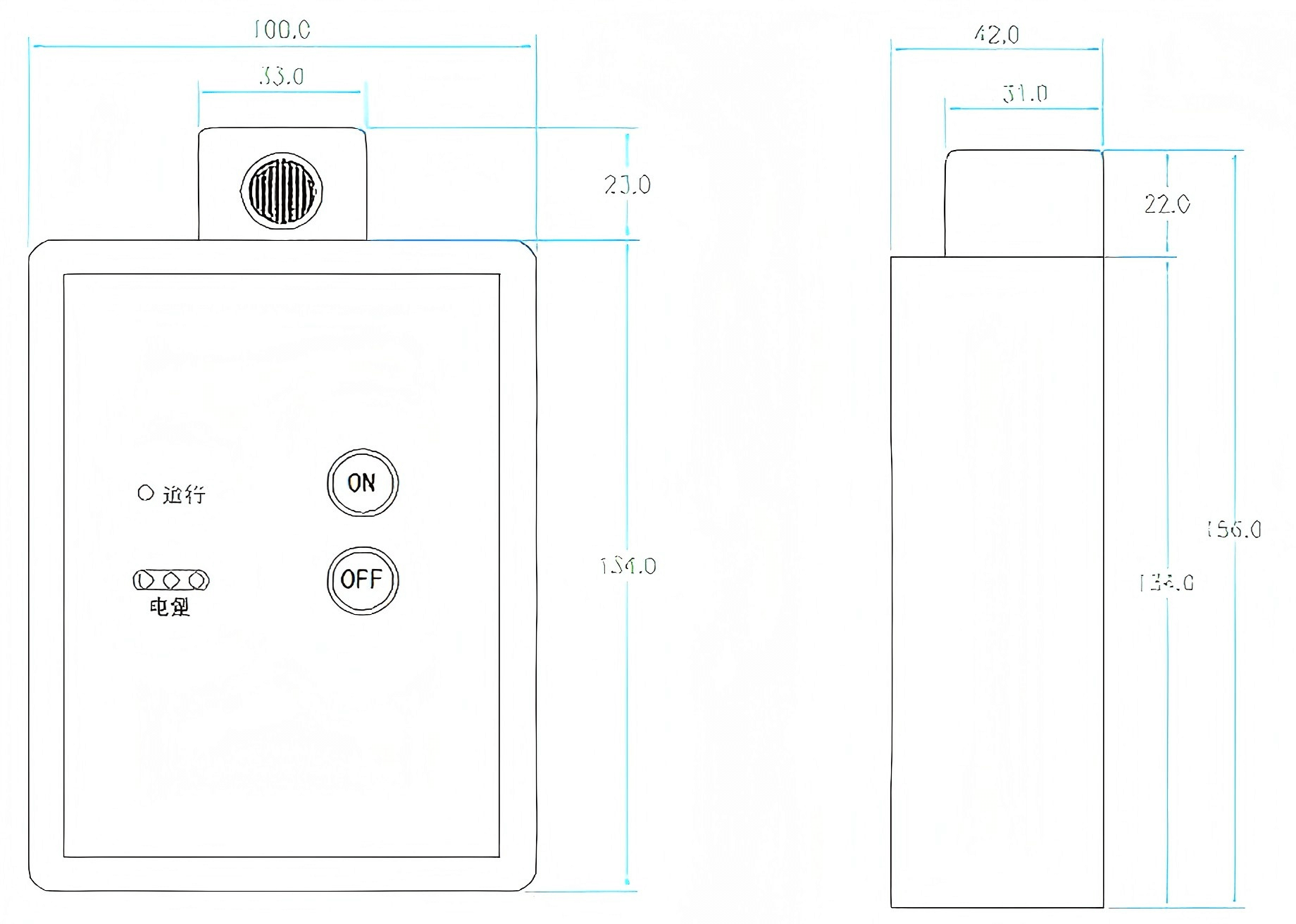

APD300-W triple-in-one wireless partial discharge sensor adopts a high-strength magnetic mounting system, installed on the external doorpanels of either the circuit breaker compartment or cable compartment in each switchgear unit, without the need for high voltage power outageThe detailed dimensions of the product are shown in the figure, in mm.

APD300-W Dimensional

APD300-W triple-in-one wireless partial discharge sensor

Photo on Site

|

Parameters |

APD300-L |

APD300-W |

||

|

Power |

DC 12-36V |

Battery |

||

|

Battery life |

— |

3-4years, replaceable (Model 2ER18505M) |

||

|

Communication |

RS485 (MODBUS-RTU ) |

Lora |

||

|

Sampling |

4s | 2h | ||

|

PD monitoring sensors |

AE |

Measuring range |

0~60dBuV |

|

|

Resonant frequency |

40kHZ+1KHZ |

|||

|

TEV |

Measuring range |

0-60dBmV |

||

|

Bandwidth |

3MHZ~100MHZ |

|||

|

UHF |

Measuring range |

-70~10dBm |

||

|

Bandwidth |

300MHz-1500MHZ |

|||

|

Average equivalent height |

≥10mm |

|||

|

Environment |

Noise measuring range |

30dB~130dB |

||

|

Temp measuring range |

-40℃~85°C |

|||

|

Humidity measuring range |

0~100%RH |

|||

|

Usage environment |

Temperature |

-40℃~85°C |

||

|

Relative humidity |

≤95%RH |

|||

|

Size |

Terminal form factor |

135mm*100mm*42mm |

||

|

Installation |

Installation |

Magnetic |

||