As we all know, energy is an important engine of economic development and it is also the lifeblood of the national economy. The mining industry has always been the important pillar of the energy industry. China’s mining production mainly comes from underground where the environment is harsh. For example, there are five natural disasters: water, fire, gas, coal dust, and coal seam roof. In addition, the production environment is complex and it’s easy to cause the fatal accidents.

For safety reasons, the low-voltage power distribution system in the mine adopts an IT system. It is a system that neutral is ungrounded and conductive part of the load is directly grounded (PE line). The features of the IT system is that when the first grounding fault occurs, the current of grounding fault is very small, the voltage of exposed conductive part to ground is below 50V, It is unnecessary to cut off the fault circuit immediately, so it can ensure the continuity of power supply. But at this time, the voltage of non-fault relative to ground will increase by 1.732 times, and the requirement for line withstand voltage will increase. At the same time, once a secondary grounding occurs, it will lead to a dangerous phase-to-phase short-circuit, so an insulation monitoring device should be installed which can help eliminate hidden dangers in time when the first grounding occurs.

For the coal mine as the typical representative of underground environment, in the process of mining, due to limited space, long in depth, humid air, dustiness, waterlogged roadway, and many other adverse factors, it is easy to cause the cable insulation resistance and electric equipment aging and decline, the underground equipment and cables often suffer from insulation strength reduction, single-phase leakage or single-phase grounding fault, If not handled in time, it may further develop into phase to phase short circuit. As a result, underground workers are more vulnerable to electric shock than they would be in a regular environment, and may also cause explosion of gas and coal dust.

Obviously, It has more important significance for the real-time insulation monitoring of mine IT system.

However, it is expensive to use imported brand insulation monitoring devices, and the human-computer interface is often in English, which is not conducive to the use of field workers. There are also domestic enterprises which have gradually launched their own industrial insulation monitoring devices, including the AIM-T series insulation monitoring devices of Acrel.

1.Online monitoring status of insulation monitors at home and abroad

At the beginning of the founding of the People's Republic of China, China's electrical design was based on the former Soviet Union's electrical code, mainly using TN-C system. It can save a PE line, which is more economical, but there are many disadvantages, such as, after the neutral line breaks, the equipment shell to the ground will have a dangerous contact voltage of 220 V, and RCD cannot be installed to prevent electric shock, etc. After the reform and opening up, China has introduced the standards of IEC, and with the continuous improvement of electrical technology in China, TN-S, TT and IT systems have been promoted and applied to a certain extent.

For example, the application in medical IT is relatively mature at present, but in many industrial occasions, due to the understanding and application of grounding system is not thorough and comprehensive, for example, the lack of domestic insulation monitoring device in coal mine is a proof.At present, the insulation monitoring devices of mine underground IT system are mainly imported brands. Insulation detection technology have been widely used in IT distribution network in developed countries such as Europe and the United States. And they have accumulated a lot of monitoring data and experience after a long-term online operation. This is what domestic manufacturers need to learn and catch up with.

However, it is expensive to use imported brand insulation monitoring devices, and the human-computer interface is often in English, which is not conducive to the use of field workers. There are also domestic enterprises which have gradually launched their own industrial insulation monitoring devices, including the AIM-T series insulation monitoring devices of Acrel.

2.Acrel industrial insulation monitor

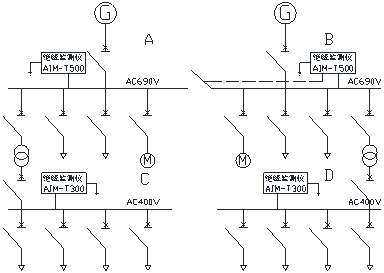

AIM-T series insulation monitor is mainly used in IT power distribution system of industrial site, including AIM-T300, AIM-T500 and AIM-T500L, which are all applied to pure AC, pure DC and AC / DC hybrid systems.

AIM-T300 is suitable for AC, DC and AC / DC hybrid systems below 450V, and AIM-T500 is suitable for AC, DC and AC / DC hybrid systems below 800V. AIM-T500L has the function of insulation fault location compared with AIM-T500.

1) The technical parameters of AIM-T series products are shown in the table below

|

Model |

AIM-T300 |

AIM-T500 |

AIM-T500L |

||

|

Auxiliary power supply |

Voltage |

AC85…265V |

AC85…265V |

||

|

Power consumption |

<8W |

<8W |

|||

|

Monitored IT system |

Voltage |

0…480V AC/DC |

0…690V AC 0…800V DC |

||

|

Frequency |

40…60Hz |

40…60Hz |

|||

|

Insulation monitoring |

Measuring range |

1kΩ…5MΩ |

1kΩ…10MΩ |

||

|

Alarm value range |

10kΩ…5MΩ |

10kΩ…10MΩ |

|||

|

Relative error |

1…10k: 10k; 10k…5M: ±10% |

1…10k: 10k; 10k…10M: ±10% |

|||

|

Allow system leakage capacitance |

<150uF |

<500uF |

|||

|

Response time |

<6s |

<5s |

|||

|

Internal parameters |

Measuring current |

<170uA |

<270uA |

||

|

Insulation fault location |

—— |

—— |

YES |

||

|

Electromagnetic compatibility / radiation |

IEC61326-2-4 |

IEC61326-2-4 |

|||

|

Rated impulse voltage / pollution level |

8kV/Ⅲ |

8kV/Ⅲ |

|||

|

Internal DC resistance |

≥120kΩ |

≥180kΩ |

|||

|

output |

Relay output |

Early warning and alarm |

Error, warning, alarm |

||

|

Environmental |

working temperature |

-15…+55℃ |

-15…+55℃ |

||

|

Storage temperature |

-20…+70℃ |

-20…+70℃ |

|||

|

relative humidity |

5%…95%, No dewing |

5%…90%, No dewing |

|||

|

Altitude |

≤2500m |

≤2500m |

|||

|

communication |

|

RS485, Modbus-RTU |

RS485, Modbus-RTU |

||

2) The typical application of AIM-T series products is shown in the following figure:

4.Summary

At present, Acrel AIM-T series industrial insulation monitor has been applied in the IT system of many industrial occasions, such as mine, paper industry, ship, metallurgy plant, etc. It can monitor the insulation condition of the system to the ground in real time. When the system has insulation drop or ground fault, it can alarm and remind relevant person to check the fault, which has a good monitoring and prevention effect in the application.

Bibliography

1.Solutions for enterprise micro-grid system