Abstract: Introduce the Pepsi Asia R&D Center, which uses smart power meters to collect various electrical parameters and switch signals at the distribution site. The system adopts the method of on-site networking. After networking, it communicates through fieldbus and transmits it to the background. The Acrel-2000 power monitoring system realizes real-time monitoring and management of power in distribution stations.

Keywords: Distribution stations;Intelligent power meter;Power monitoring system

1.Project Overview

Pepsi Asia R&D Center is located in Pujiang High-Tech Park, Caohejing Development Zone. The R&D center is PepsiCo’s largest top R&D center outside North America and one of Pepsi Co’s most integrated food and beverage R&D centers in the world. It plays a pivotal role in PepsiCo’s global R&D network. The Pepsi R&D Center in Asia covers an area of about 25 acres and has a building area of nearly 20,000 square meters.

The center also has a test production plant that allows developers to quickly test new products and supports PepsiCo to accelerate R&D in China and other growing Asian markets Innovation. This project undertakes part of the monitoring system of its substation and distribution station.

2.Structure

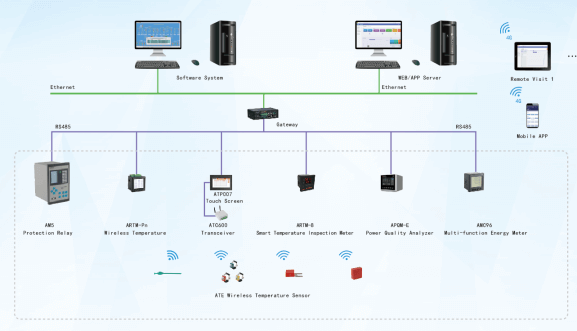

According to the actual situation of Pepsi Asia R&D Center, Acrel power monitoring system adopts shielded twisted pair cable to connect directly to the data collector of the power distribution station. Then it is directly connected to the monitoring host of the switching station to ensure the stability and real-time transmission of the power monitoring system of the distribution station.

3.Related Products

|

Name and Type |

Picture |

Description |

|

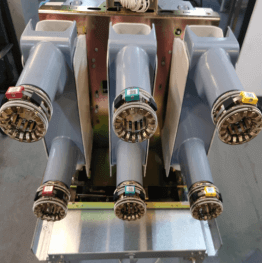

● 8 current input, 6 voltage input, 20DI, 10 DO; ● 2 RS485 serial communication and Modbus-RTU; ● 1 RS232 for user update; ● 1 GPS for GPS timing; |

||

|

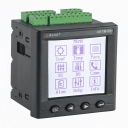

ACR230ELH AC Panel Meter Three phase energy meter

|

|

● U, I, P, Q, Ep, Eqmeasurement ● THD with 2-63rd harmonics ● Multi tariff ● Wave form real time display and SOE event record ● RS485 communication, Modbus-RTU |

|

● U, I, P, Q, Ep, Eq, True RMS measurement ● THD with 2-31st harmonics ● RS485 communication, Modbus-RTU. ● Internal optional: 4DI/2DO or 2DI/2DO/2AO |

||

|

● Measuring 60 points; ● U, I, P, Q, f, Ep, Eq measurement; ● 4 digital inputs; ● 2 alarm relays, high temperature alarm; ● LCD display; ● Power supply adapt with AC220V, DC220V, DC110V, AC110V; ● 1 RS485 serial communication, Modbus-RTU. |

||

|

● 8 PT100 measurement; 2 Alarm relays; ● LED display; ● Auxiliary power supply adapts with AC220V, DC220V, DC110V; ● 1 RS485 serial communication, Modbus-RTU; |

||

|

● Measuring 60 points; ● 1 RS485 serial communication, Modbus-RTU; ● Power supply adapt with DC24V. |

||

|

● Measuring 240 points; ● 1 RS485 serial communication, Modbus-RTU; ● 2 alarm relays; ● Power supply adapt with AC/DC220V, AC/DC110V. |

||

|

● Wireless transmission distance, 150 meters; ● Fase sampling frequency, 15s; ● CT-powered, more than 5A starting current; ● Widely temperature measuring range, -40℃~125℃ |

||

|

● Wireless transmission distance, 150 meters; ● Fase sampling frequency, 25s; ● Battery-powered, more than 5 years; ● Widely temperature measuring range, -40℃~125℃ |

||

4.Project Summary

In the application of today's power distribution facilities, power distribution safety is of paramount importance. The Acrel-2000 power monitoring system described in this article is used in PepsiCo Asia R&D Center. It can realize the real-time monitoring of the power consumption of the power supply and distribution circuit of the power distribution station, not only can display the power consumption of the circuit, but also has the network communication function, and can form a power monitoring system with the communication management machine and computer.

The system analyzes and processes the collected data and displays the operating status of each power distribution loop in real time. It has a pop-up alarm dialog box, voice prompt, SMS alarm light, and generates various electric energy reports, analysis curves, graphics, etc. It is convenient for remote meter reading, analysis and research of electric energy. The system is safe, reliable and stable in operation, and provides a true and reliable basis for large-scale public buildings to solve electricity problems.

5.Photos on Site