0.Background

October 17th, 2018, Shanghai Lin-Gang management committee confirmed the Tesla (Shanghai) Co., LTD has successfully won the land mass Q01-05 l, 864885 m² of industrial land.

On January 7th, 2019, first step construction of Tesla factory was announced at the intersection of LiangGang West Avenue and ZhengJia Road, located in the southeast corner of Shanghai.

The plant is scheduled to have an annual capacity of 250, 000 electric vehicles at the first step, including models such as the Model 3. In March 2019, the first step of Tesla factory construction was finalized as Shanghai Construction Engineering Group, a local construction company in Shanghai.

The Shanghai factory is Tesla's another factory besides the United States and will start construction in January 2019.

1.Overview

This project is the second step of Tesla's Shanghai Lingang Factory. This project includes 3 distribution rooms, including energy center C2, union workshop 4 and substation incoming isolation cabinets, with totally 60 sets of 10kV high voltage cabinets.

2.Product Solution

2.1 Product requirements

For the project of Tesla Shanghai Lingang factory, smart control device is required to monitor the state of all high-voltage cabinets in the power distribution cabinet in the distribution room.

The requirements of the project are as follows:

● A dynamic simulation diagram, electrical display and blocking;

● Temperature and humidity control, LED display;

● Switch on and off, energy storage, remote/local switch;

● Voice prompt and human body induction;

● Lighting operation in the cabinet;

● RS485/ Modbus communication.

In order to meet the above requirements, we choose ASD200 smart control device. The external structure of Acrel ASD200 intelligent control device is as follows:

2.2 Project solution

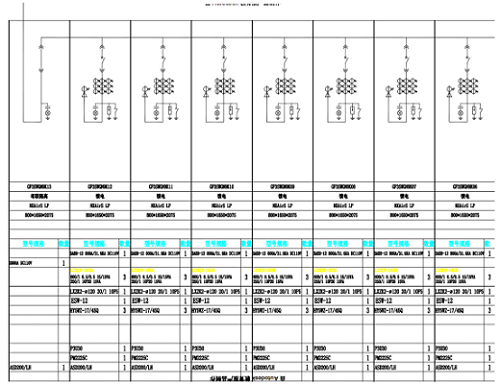

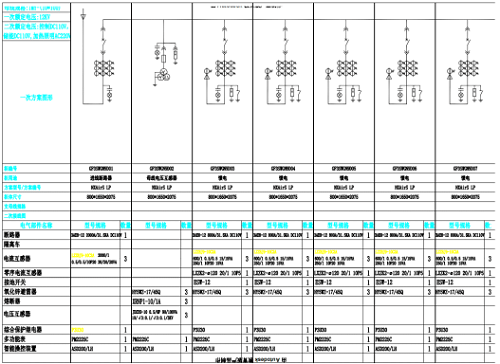

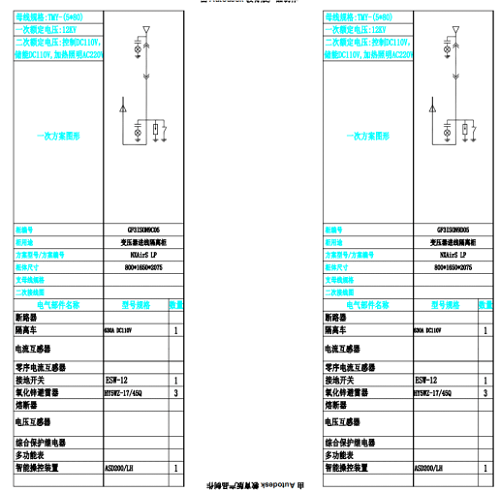

For the 3 distribution rooms of the project, including energy center C2, joint workshop 4 and substation incoming isolation cabinets, there are totally 60 sets 10kV high voltage cabinets. Taking part of 10kV high voltage distribution cabinets as example, the products smart control device are shown in the figure below:

2.3 Product detail

The smart control device ASD200 is used in this Tesla project, totaling 60 pcs. The product introduction is shown in the table below.

|

Function & Type |

ASD100/ASD100G |

ASD200 |

ASD300 |

ASD310 |

ASD320 |

|

|

Product picture |

|

|

|

|||

|

Cutout |

112mm×172mm |

220mm×165mm |

||||

|

Primary circuit analog chart |

Standard |

|||||

|

Live display and self-test/check phase |

Optional |

|||||

|

Electromagnetic lockout outlet |

1 channel |

2 channel |

1 channel |

|||

|

Temperature/humidity control |

Standard 1 channel , length 4m sensor cable |

|||||

|

1 channel heating, 1 blowing |

2 channel heating |

2 channel heating,1 channel blowing |

||||

|

Forced heating |

Standard |

Standard |

||||

|

Heating circuit Fault alarm |

Standard |

None |

||||

|

Voice prompts |

None |

Standard |

||||

|

Sensing probe for human movement |

None |

Standard |

||||

|

Operating switch |

None |

Optional |

||||

|

Beaker on/off shows |

None |

Standard |

||||

|

Wireless temperature sensor |

None |

None |

Optional |

None |

Optional |

|

|

Measure and display of power parameter |

None |

None |

Standard |

None |

||

|

RS485 Communication |

None |

Standard |

||||

3.Other Related Products

For large production enterprise power distribution project, in order to provide the safety and reliability of power supply, Acrel also launched the switchgear electrical connection point temperature monitoring products, you can real-time monitor copper platoon, cable, contained in the circuit breaker plum touch the top temperature of the electrical connection, convenient operation maintenance of the entire transformer room. The following is the selection scheme of electrical node temperature measurement products of switch cabinet.

|

Name |

Shape |

Parameter Instruction |

Installation |

|

Panel 96*96*17mm, depth 65mm, opening 92*92mm, AC85-265V or DC100-300V power supply; along the way line RS485 interface; can receive 60 ATE wireless temperature sensors include ATE100M/100/200/400/ATE100P/ATE200P (matching ATC450); Modbus protocol. |

Embedded panel installation |

||

|

ASD300/320 |

|

Panel 237.5*177.5*15.3mm, depth 67mm, opening 220*165mm; AC85-265V or DC100-300V power supply; line RS485 interface along the way; can receive 12 wireless temperature sensors include: ATE100M/100/200/400(matching ATC450); Modbus protocol. |

Embedded panel installation |

|

ATP007 |

|

Panel 226.5*163*6mm, depth 70mm; hole 215*152mm; DC24V power supply; 1 channel uplink RS485 interface, 1 channel downlink RS485; can receive 4 ATC450-C or 1 ATC600.

|

Embedded panel installation |

|

Panel 96*96*12.5mm, depth 70mm, hole 88*88mm; along the way RS485 interface, can be connected to 8 channels of temperature sensor; Modbus protocol. |

Embedded panel installation |

||

|

Acrel-2000T/A |

|

The size of the cabinet is 480/420/200mm; DC220V power supply; 1 channel uplink RS485, the downlink is one Ethernet port, and 4 sets ATC450-C or 1 set ATC600 can be received. |

Wall mounted |

|

Acrel-2000T/B |

|

The size of the cabinet is 480/420/200mm; Hardware: memory 4G, hard disk 128G, Ethernet port; displayer: 12 inches, resolution 800/600; operating system: Windows 7; database system: Microsoft SQL Server 2008 R2; I/O interfaces: GLAN×2, USB×4, COM×6; Optional Web platform/ APP server |

Wall mounted |

4.Summary

This article introduces the application of Acrel smart control products in project of Tesla Shanghai Lingang factory, aiming at the integrated measurement and control in the high-voltage switch cabinet, and the device is widely used in power plant, power system distribution network, factory and construction and other fields.

Smart control device can replace live display instrument, temperature and humidity controller, switch position signal lamp, control switch (button), analog plate and electrical measuring instrument and other traditional secondary components, so that the switch cabinet disk clean, beautiful, easy to debug and maintain, to achieve operation and display in one.

Bibliography

1、Solutions for enterprise micro-grid system