Abstract: this paper analyzes the principle of low voltage split core current transformer, analyzes the application and construction details of split core current transformer in low voltage distribution system with engineering examples, and provides a solution for users to realize intelligent distribution quickly. The scheme has the advantages of low cost, low investment and simple installation and wiring, which is beneficial to the further popularization and application of low voltage intelligent distribution.

Keywords: Split core current transformer; Low Voltage Distribution System; Renovation Project; Principle; Application; Construction Details

1.Introduction

At present, most of the low voltage current transformers in the market are mainly used in the construction of new projects. Due to the rapid development of economy, the awareness of energy saving and emission reduction is gradually improved. The electrical characteristics of many enterprises are:

1) Long running time of electric gas cabinet;

2) Most of the current transformers only measure the current of the system, and there is no corresponding metering device and protection device. The measuring device has only one master table of the power supply bureau, but the electric energy of all workshops can not be assessed, and the system line protection device is not available at all;

3) Most of the main lines are large size copper bar, it takes a lot of manpower and time to disassemble, it is not convenient to install conventional current transformer;

4) Enterprise production time is more urgent, can not long time blackout.

Therefore, the use of split core current transformer can save a lot of investment for users.

2.Product Design

1) Structural characteristics

Our company has a complete range of split core current transformer models, including round hole transformers for cables, and square hole transformers for copper bars, this product shell material is PC/ABS alloy, with high temperature resistance, high mechanical strength, environmental protection and other characteristics; the core adopts oriented cold bonded silicon steel sheet with stable performance, high mechanical strength and high magnetic conductivity.

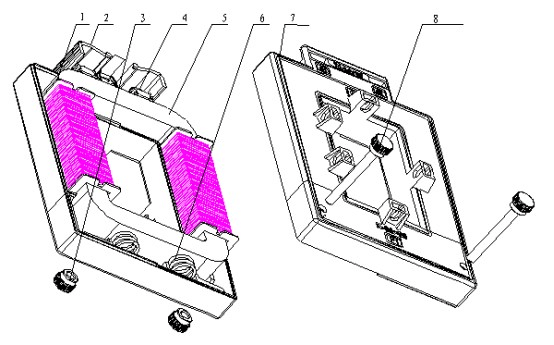

Figure.1

1-Skeleton coil, 2-transparent flip, 3-mount nut, 4-wiring terminal, 5-core, 6-spring ,7-shell, 8-mount screw.

2) Working principle of open current transformer

The working principle of the low voltage split core current transformer is shown in figure 1, the primary winding of the split core current transformer is connected in series in the line under test, I1 is the primary current of the current transformer, N1 is the primary turn of the current transformer, I2 current transformer secondary current (usually 5 A、1A), N2 is the secondary turns of the current transformer, Z2e for secondary circuit equipment and connection wire impedance.

As the primary current flows through the P1 end of the current transformer, P2 out, If the secondary Z2e is connected, based on electromagnetic induction, the secondary winding of the current transformer has current I2 flowing through the S1, Z2e to S2, Form a closed loop. Hence the I1×N1=I2×N2, of current in ideal state And so there's I1/I2=N1/N2=K, K is the ratio of current transformer. But since the core of the open current transformer is cut, Make the core performance will be more powerful, So the cross section of the transformer core must be increased, And increase the number of turns, I1×N1=I2×N2≥100 AN.

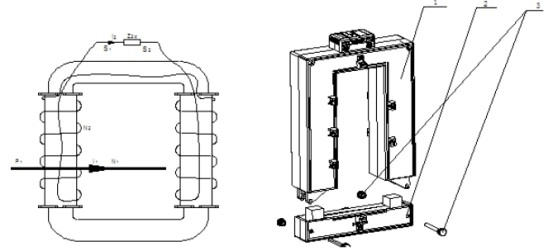

Figure.2

Note: Figure 2- Upper body of the 1- Open current transformer, 2- Lower body of the 2- Open current transformer, 3- Install screws, nuts

3) Product installation

As shown in figure 2, the installation screws and nuts of the transformer are opened, the lower body of the transformer is unloaded, the upper body of the transformer is loaded into the primary bus row of the distribution system, the lower body of the transformer is closed, the installation screw of the transformer passes through the fixed hole of the upper and lower body of the transformer, the nut is screwed, the upper and lower body of the transformer is fixed together, and then the transformer is fixed on the bus row through the installation fixing hole on both sides of the transformer to complete the installation of the transformer. Then connect the secondary of the transformer to the measuring device. The whole process is relatively fast and simple.

3.Application

Split core current transformer is mainly used in the low voltage distribution transformation project. Split core current transformer is output as standard 5 A or 1 A, as the conventional closed current transformer. The measuring precision is high and the capacity is large.

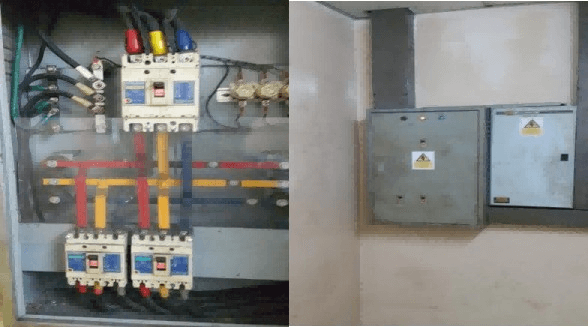

For example, as shown in figure 3, each line needs to measure three-phase current, supply the collected current signal to the watt-hour meter DTSD1352, transmit the data to the industrial cloud system of the United States after networking. A phase, B phase, C phase can choose our round hole type open transformer, each phase rated current is 400 A, adopt AKH-0.66/K K-∮36 The 400/5 split core current transformer collects current signals.There is no need to remove wires or copper bars on site.

Figure.3

4.Summary

Split core current transformer has been used in the engineering distribution monitoring system of industrial and mining enterprises in many countries, which reduces the investment cost, provides the working efficiency and reduces the working difficulty.

Bibliography

1.Solutions For Enterprise Micro-grid System 2020.02